Extruders are divided into single-screw extruders, twin-screw extruders, and triple-screw extruders. These three types of extruders can produce food and feed, as well as some special raw materials

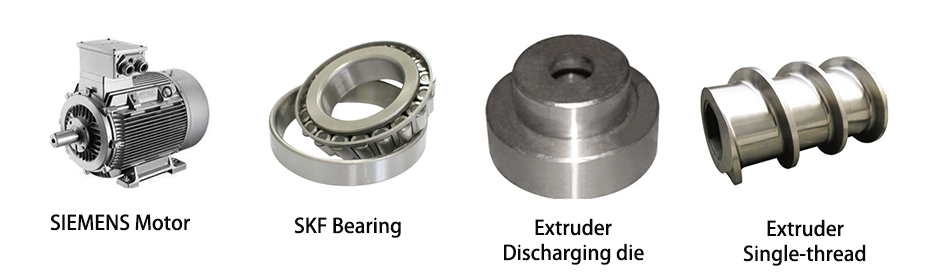

| Place of Origin | CHINA | Bearings | SKF |

| Warranty | 12 Months | Motor | Siemens Brand |

| Voltage | Clients' Requirement | Certificate | ISO9001 |

| Color | Clients' Requirement | Payment Type | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Transportation | Ocean,Land | Incoterm | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP,DDU |

Extruders are divided into single-screw extruders, twin-screw extruders, and triple-screw extruders. These three types of extruders can produce food and feed, as well as some special raw materials

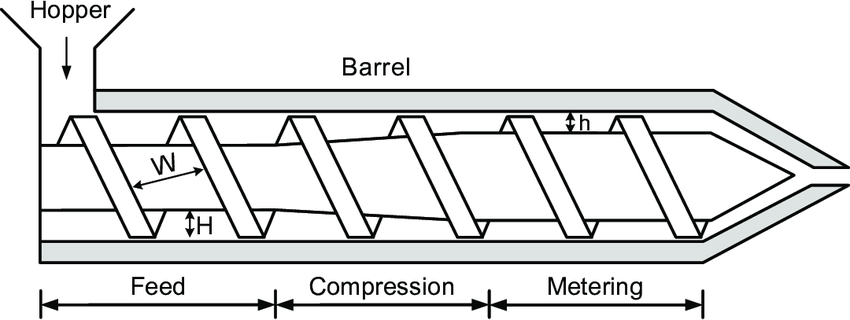

1. The single-screw extruder consists of one screw to form the extruding chamber. Single-screw generally does not have external heating, and only in extremely cold regions or when soybeans are produced by dry method, the external heating of the screw will be done. Therefore, in single-screw extrusion, the shear heat is guaranteed by the rotational speed, and the general single-screw rotational speed is 480-600 rpm.

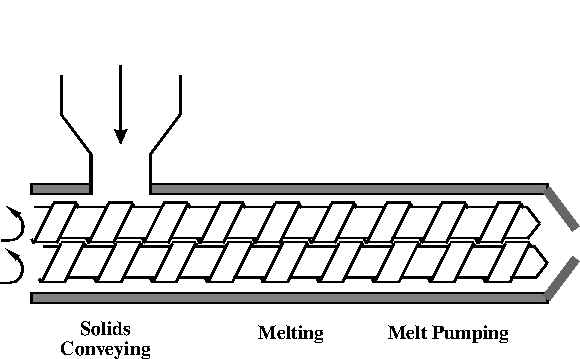

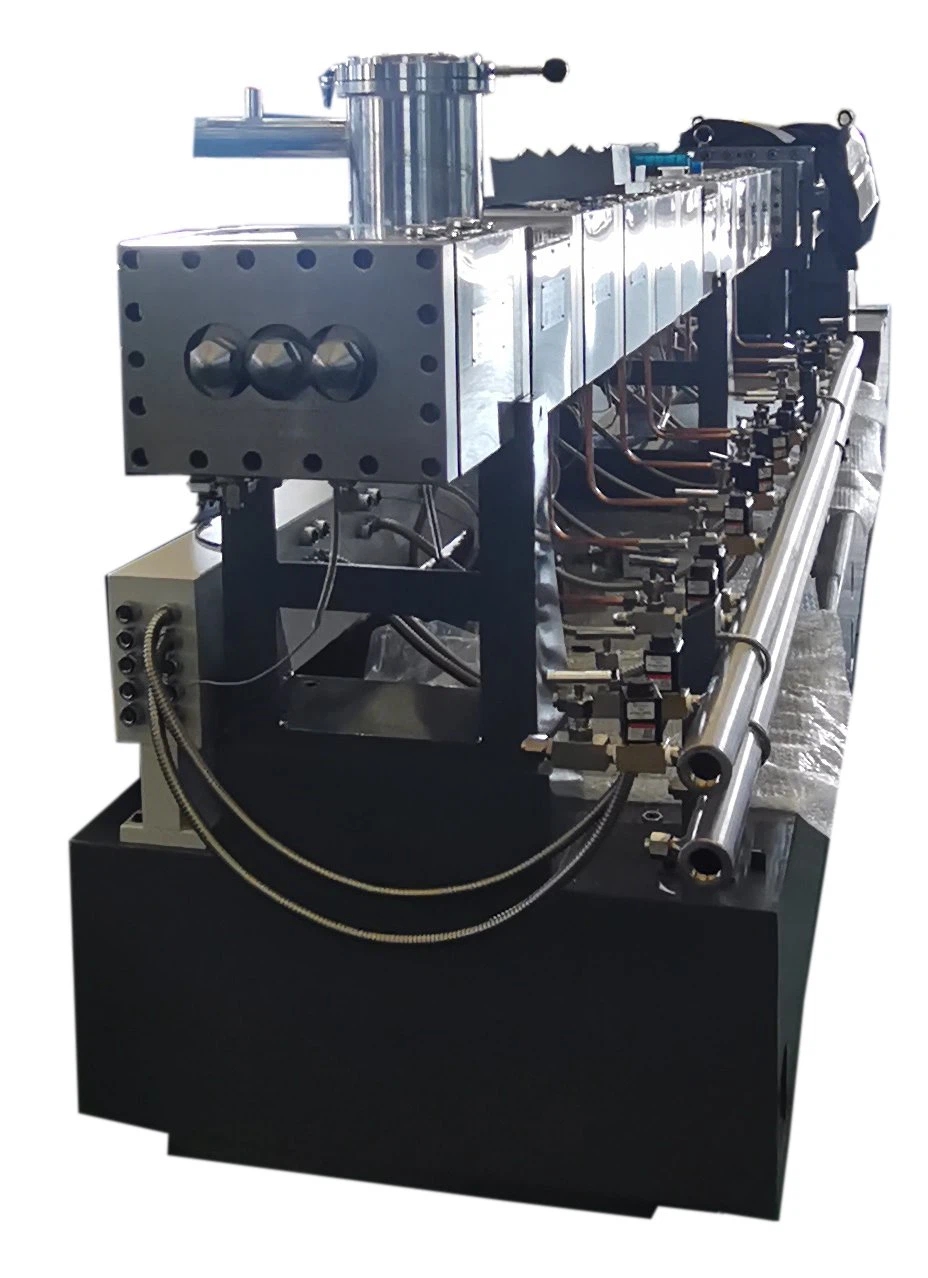

2. The twin-screw extruder is composed of two screws in the puffing chamber, and the two screws are combined to form a set of meshing areas. While the materials are running in parallel in the puffing chamber, the effect of mixing and shearing is increased, so it is more efficient than single-screw. It is suitable for the production of mixed formula feed.

3. The three-screw extruder is composed of three screws in the puffing chamber, and the three screws shear each other, which is equivalent to three sets of twin-screws operating simultaneously in one puffing chamber, with three meshing points, so the shearing efficiency is high and the material is easy to plasticize , At the same time, the pressure generated before puffing is greater, the degree of ripening is better, and the amount of nutrients such as protein and fresh meat is more added. Energy consumption is 30% lower than that of twin-screw extruders with the same output.

The Extruder are further divided into dry-process extruders and wet-process extruders.

1. Dry-process extruders use friction and shear between the screw barrel and the screw to generate heat, supplemented by heating wrapped around the outside of the screw barrel. The external heat of the ring heats and extrudes the material, and the production method of puffing is more common in the small feed factories. In addition, small food industry also use dry production, which has low investment costs and quick capital return.

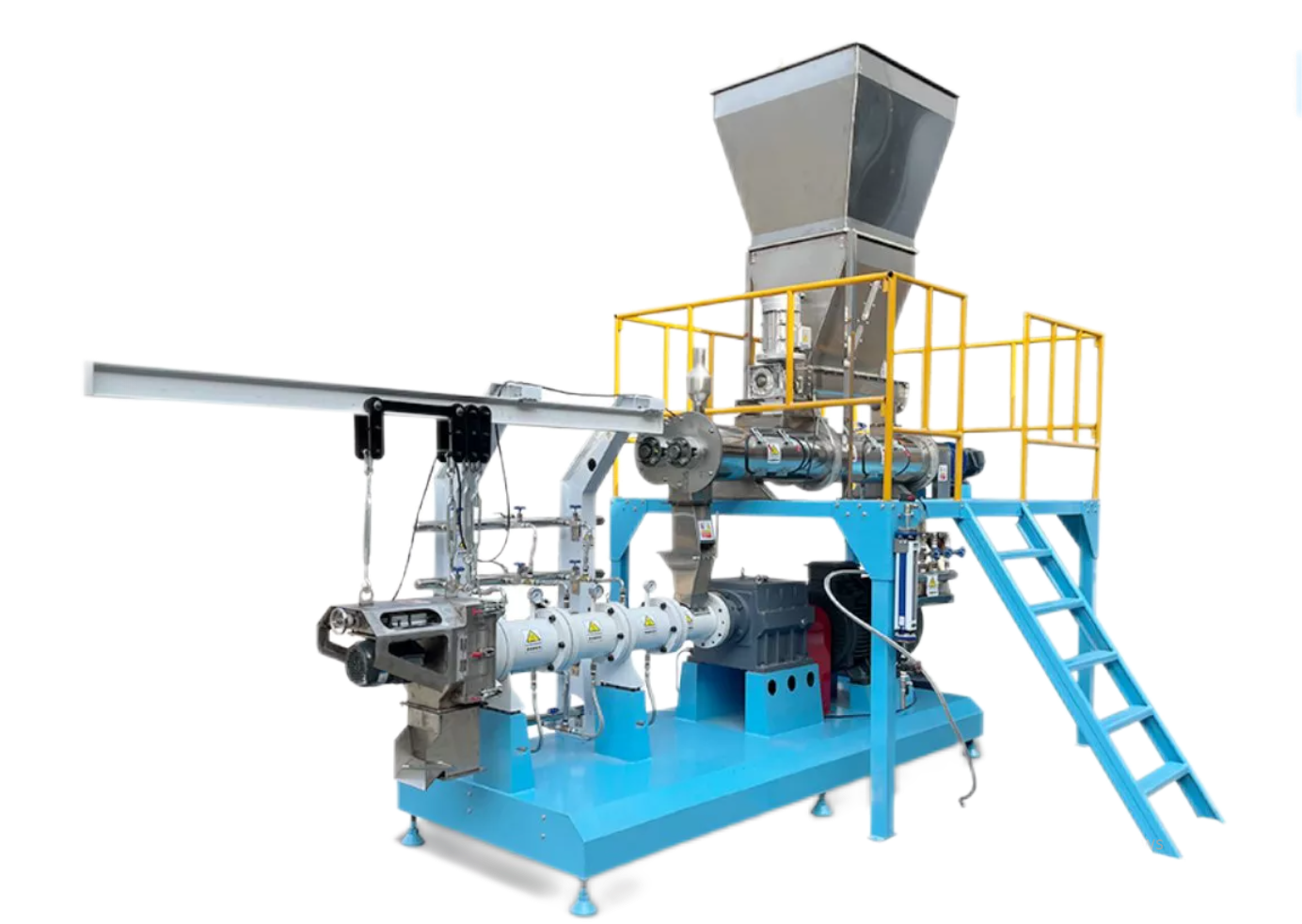

2.Eet-production Extruder use steam (generally the pressure is 0.3-0.4mpa and the temperature is 140-150°C) to preheat the material in the conditioner to 70-100°C, supplemented by the extruder’s own heat generation and screw barrel The production method of external heating (it can be steam water pipe or electric heating sheet) is commonly used in the production of aquatic feed, pet food, extruded corn feed, soybean feed, etc.

Application Of Extruder

It uses corn, soybean (bean cake) animal wastes as raw materials, can be expanded to produce different particle shapes, suitable for different pet tastes such as fish,shrimps,pet, birds, Crab etc.

Technical Parameters

Dry-process extruders

| Model | Capacity(T/H) | Main Motor Power(KW) | Feeder Motor Power(KW) | Screw diameter (mm) | Cutter power (kw) |

| ZNPH60C | 0.10-0.15 | 15 | 0.4 | Φ60 | 0.4 |

| ZNPH70C | 0.18-0.20 | 18.5 | 0.4 | Φ70 | 0.4 |

| ZNPH80C | 0.2-0.3 | 22 | 0.6 | Φ80 | 0.6 |

| ZNPH90C | 0.3-0.4 | 37 | 0.6 | Φ90 | 0.8 |

| ZNPH120C | 0.5-0.6 | 55 | 1.1 | Φ120 | 1.5 |

| ZNPH135C | 0.7-0.8 | 75 | 1.1 | Φ133 | 2.2 |

| ZNPH160C | 1.0-1.2 | 90 | 1.5 | Φ155 | 3.0 |

| ZNPH200C | 1.8-2.0 | 132 | 2.2 | Φ195 | 3.0-4.0 |

Eet-production Extruder

| Model | Capacity(T/H) | Main Motor Power(KW) | Feeder Motor Power(KW) | Screw diameter (mm) | Cutter power (kw) | Conditioner power(kw) |

| ZNPH60B | 0.18-0.20 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| ZNPH70B | 0.25-0.30 | 18.5 | 0.4 | Φ70 | 0.4 | 0.75 |

| ZNPH80B | 0.35-0.40 | 22 | 0.6 | Φ80 | 0.6 | 1.1-1.5 |

| ZNPH90B | 0.50-0.60 | 37 | 0.6 | Φ90 | 0.8 | 2.2 |

| ZNPH120B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| ZNPH135B | 1.0-1.2 | 75 | 1.1 | Φ133 | 2.2 | 3.0-4.0 |

| ZNPH160B | 1.8-2.0 | 90 | 1.5 | Φ155 | 3.0 | 4.0-5.5 |

| ZNPH200B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Finished project

Company Profile

Xinxiang Zhongnuo Mechanical Equipment Company as a diversified high-tech enterprise we always focus on the research, design,manufacturing, marketing and technical services for feed machinery, pharmaceutical equipment, breeding equipment,vibrating sieve and conveying and mixing system.Our products can be customized according to each customers different production demand. The products are automated, high efficient and high-quality as the benchmark, providing customers with comprehensive and reasonable feed processing and breeding solutions.for the vibrating sieve we can reach to 95% separating efficiency and a bigger capacity.

Contact: Darry Zhao

Whatsapp:+8615637390520

E-mail: darryzhao@pelletequipment.com

Add: The cross of Xinzhong Road and Daoqing Road, Xinxiang city, Henan, China. 453000