Feeder to ensure that the spread of material sufficiently homogeneous, thorough cooling and significantly reduced breakage rate, adjustable range of fabrics, a small power consumption. industries.Mixing mildness and high uniformity.

| Place of Origin | CHINA | Bearings | SKF |

| Warranty | 12 Months | Motor | Siemens Brand |

| Voltage | Clients' Requirement | Certificate | ISO9001 |

| Color | Clients' Requirement | Payment Type | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Transportation | Ocean,Land | Incoterm | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP,DDU |

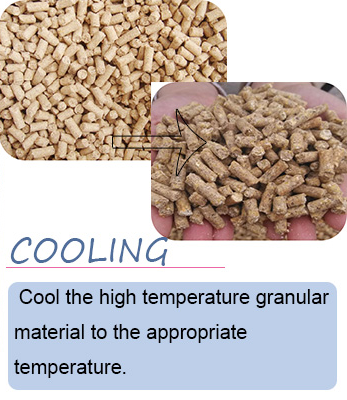

Feed Counter-Flow Cooler adopts the principle of counterflow cooling, the pellets are cooled and evenly distributed; the unique sliding valve type discharging mechanism is used for discharging; the sliding valve type discharging mechanism is stable and reliable, and the discharging is smooth; the temperature of the pellet after cooling is not higher than room temperature. +3-5 degrees. An access door is provided on the front of the unit for convenient daily maintenance and overhaul. An observation window is provided on the side for easy observation of the thickness of the material layer in the chamber.

Technical Parameters

The working principle of feed counter-flow cooler

When pellet came out from Pellet Machine, it contains determinate moisture as 8~17%, temperature around 70~85°C, if the environment air with high humidity, pellets will absorb moisture from air, and will get mildew when storage. So a Feed Pellet Cooler is needed to keep pellets dry and safe to achieve storage requirement.

| Model | Volume(m³) | Capacity(T/H) | Discharge Motor Power(KW) | Airlock Power(KW) |

| SKLN-1.0 | 1 | 1-2 | 0.75 | 0.75 |

| SKLN-2.5 | 2.5 | 3-5 | 1.1 | 0.75 |

| SKLN-4.0 | 4 | 9-12 | 1.1 | 0.75 |

The features of feed counter-flow cooler

1. Feed counter-flow cooler is suitable for cooling various kinds of pellets such as pelleted feed, expanded feeds, extruded feeds and flake feeds etc.

2. Counter-flow cooling,cool the pellets and lower humidity,after cooling the pellet temperature above room temperature 3-5 ℃ ; precipitation rate=3.5%.

3. Using slide valve discharge structure,stable and reliable operation , the residual is small.

4. There are some pressure-relief plates provided above the discharging device, which can greatly improve the working load of the discharging device, reduce SKLN series feed counter-flow cooler's distortion, and extend the service life of the component parts.

Company Profile

Xinxiang Zhongnuo Mechanical Equipment Company as a diversified high-tech enterprise we always focus on the research, design,manufacturing, marketing and technical services for feed machinery, pharmaceutical equipment, breeding equipment,vibrating sieve and conveying and mixing system.Our products can be customized according to each customers different production demand. The products are automated, high efficient and high-quality as the benchmark, providing customers with comprehensive and reasonable feed processing and breeding solutions.for the vibrating sieve we can reach to 95% separating efficiency and a bigger capacity.

T

T

Contact: Darry Zhao

Whatsapp:+8615637390520

E-mail: darryzhao@pelletequipment.com

Add: The cross of Xinzhong Road and Daoqing Road, Xinxiang city, Henan, China. 453000