PRODUCT FEATURES

Technical Parameters

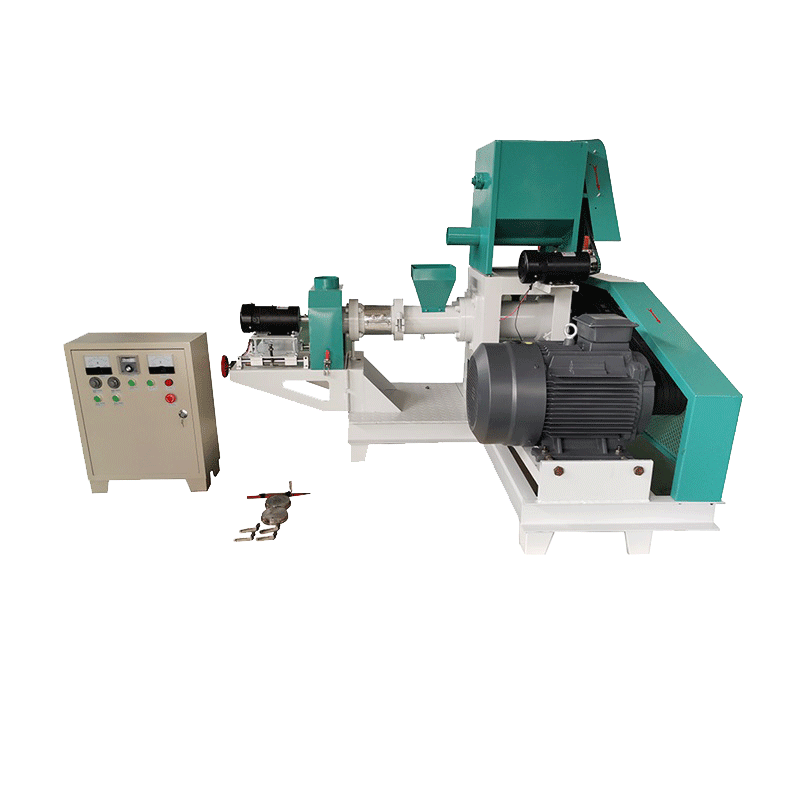

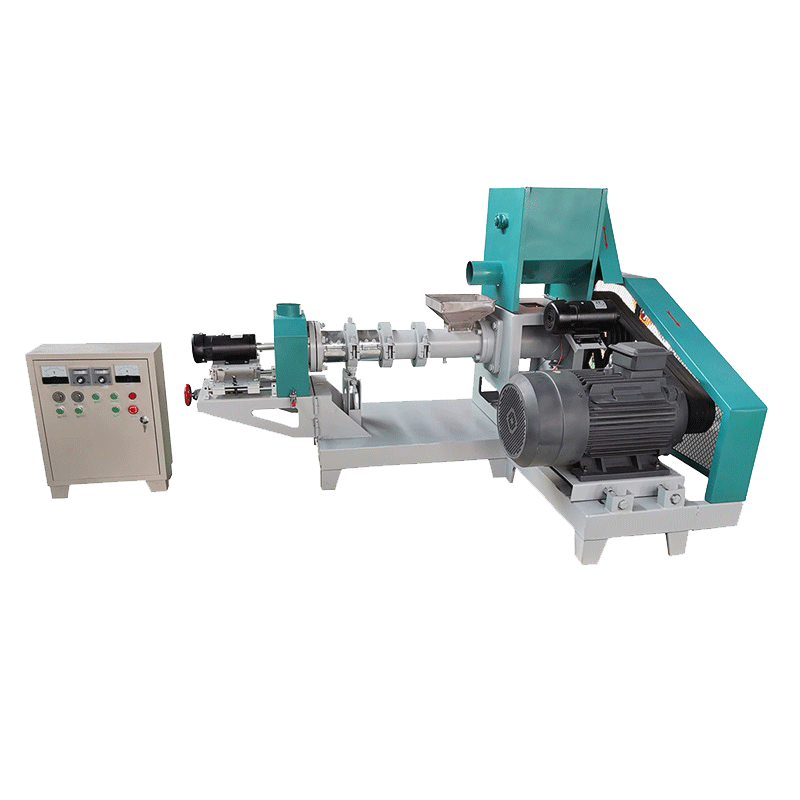

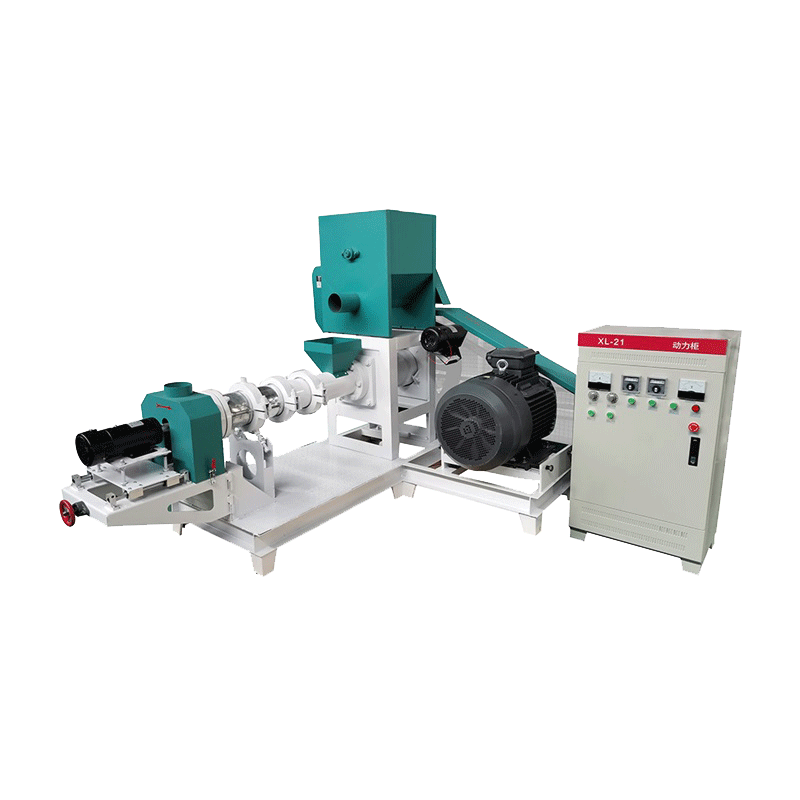

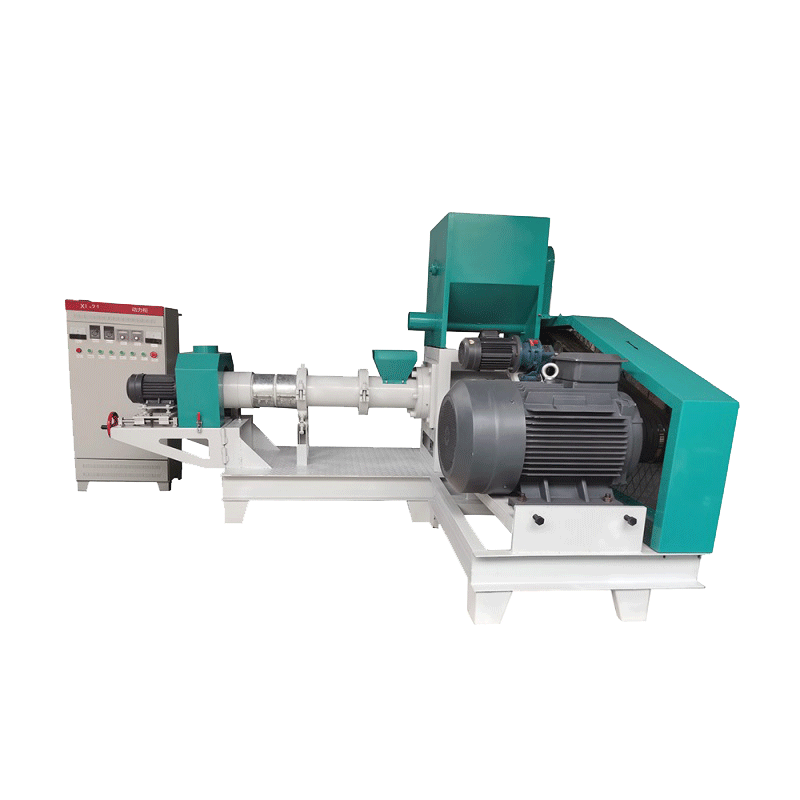

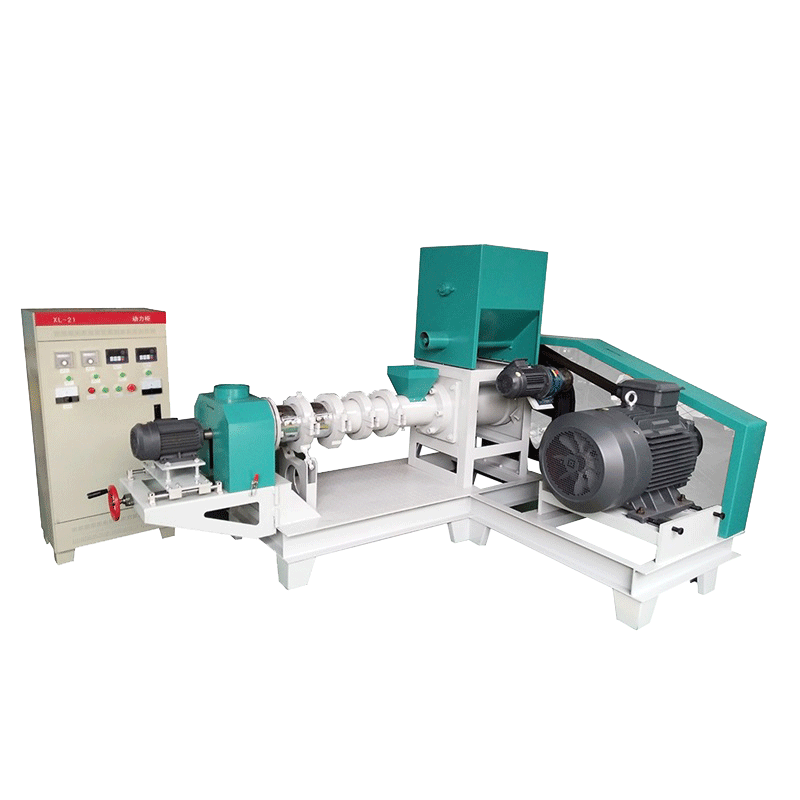

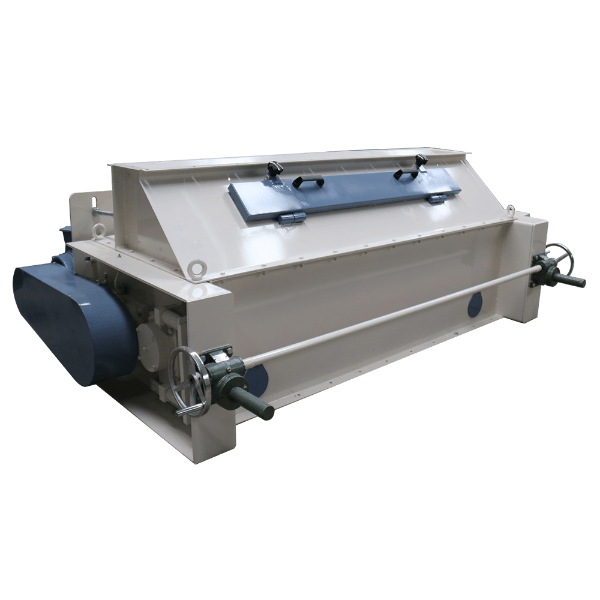

Dry-process extruders

| Model | Capacity(T/H) | Main Motor Power(KW) | Feeder Motor Power(KW) | Screw diameter(mm) | Cutter power(kw) |

| ZNPH60C | 0.10-0.15 | 15 | 0.4 | Φ60 | 0.4 |

| ZNPH70C | 0.18-0.20 | 18.5 | 0.4 | Φ70 | 0.4 |

| ZNPH80C | 0.2-0.3 | 22 | 0.6 | Φ80 | 0.6 |

| ZNPH90C | 0.3-0.4 | 37 | 0.6 | Φ90 | 0.8 |

| ZNPH120C | 0.5-0.6 | 55 | 1.1 | Φ120 | 1.5 |

| ZNPH135C | 0.7-0.8 | 75 | 1.1 | Φ133 | 2.2 |

| ZNPH160C | 1.0-1.2 | 90 | 1.5 | Φ155 | 3.0 |

| ZNPH200C | 1.8-2.0 | 132 | 2.2 | Φ195 | 3.0-4.0 |

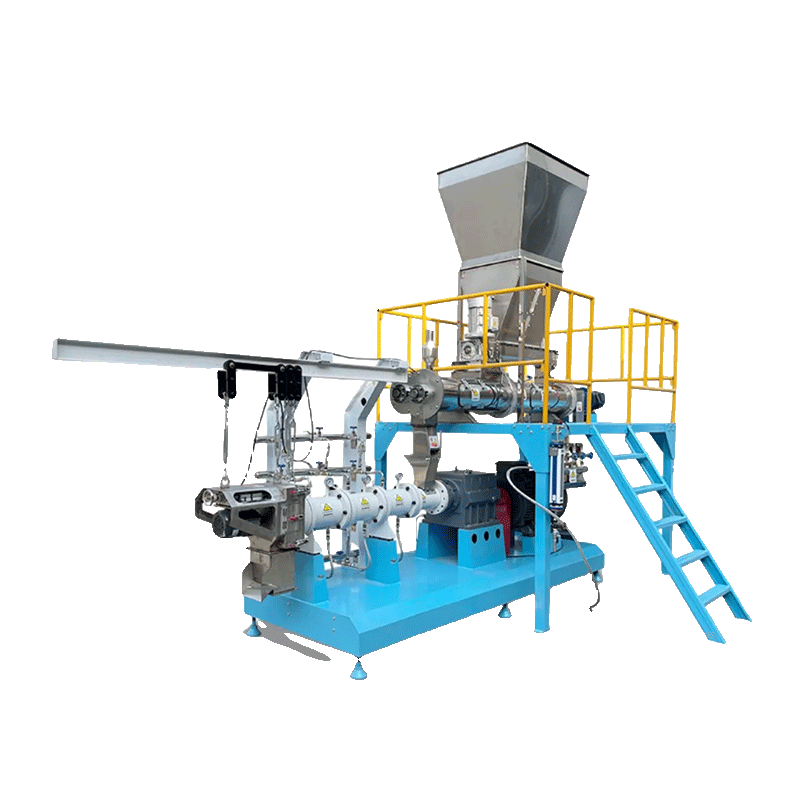

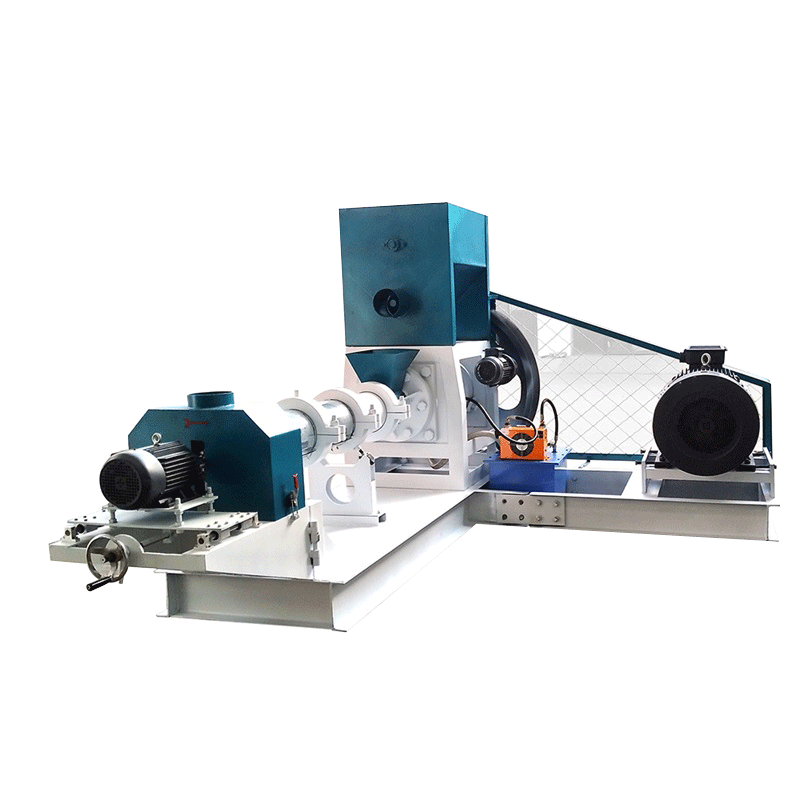

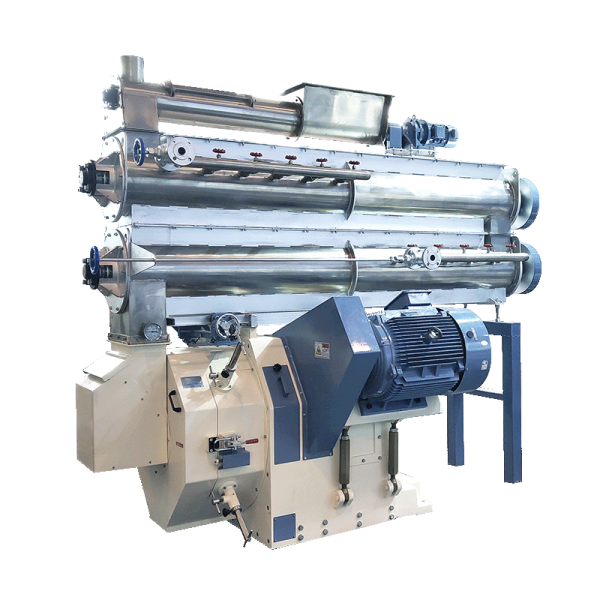

Wet-production extruders

| Model | Capacity(T/H) | Main Motor Power(KW) | Feeder Motor Power(KW) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

| ZNPH60B | 0.18-0.20 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| ZNPH70B | 0.25-0.30 | 18.5 | 0.4 | Φ70 | 0.4 | 0.75 |

| ZNPH80B | 0.35-0.40 | 22 | 0.6 | Φ80 | 0.6 | 1.1-1.5 |

| ZNPH90B | 0.50-0.60 | 37 | 0.6 | Φ90 | 0.8 | 2.2 |

| ZNPH120B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| ZNPH135B | 1.0-1.2 | 75 | 1.1 | Φ133 | 2.2 | 3.0-4.0 |

| ZNPH160B | 1.8-2.0 | 90 | 1.5 | Φ155 | 3.0 | 4.0-5.5 |

| ZNPH200B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Delivery Goods

We follow a standardized process: prepare order verificationequipmentfactory quality inspectionpacking list re-inspectionscientific packaging andtransportation to ensure safe and undamaged deliveryofequipment.